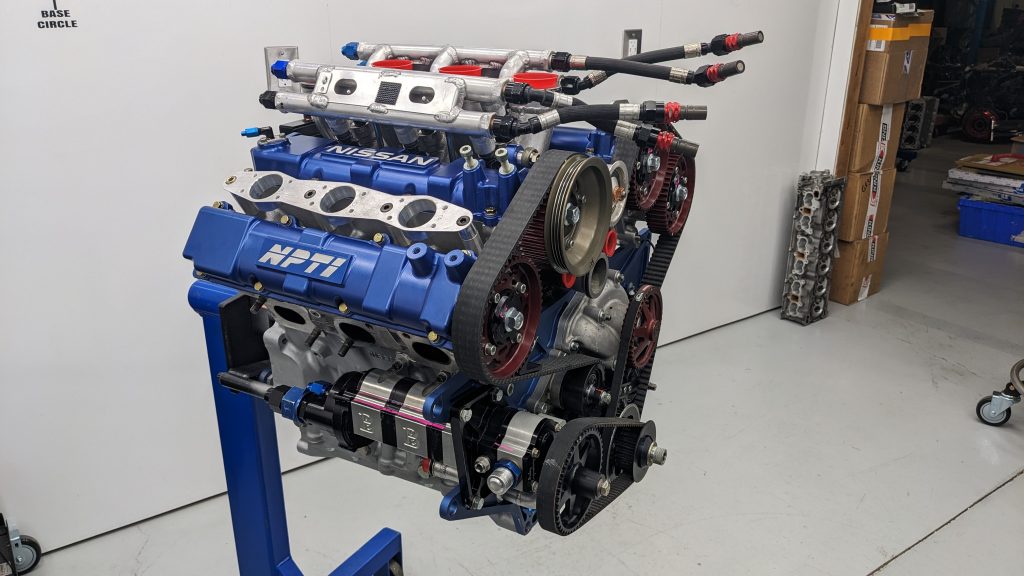

Engine building is dirty and being able to clean in the hard to reach areas for many is a chore all on its own. With so much time being spent on cleaning parts we opted to acquire another piece of cleaning equipment.

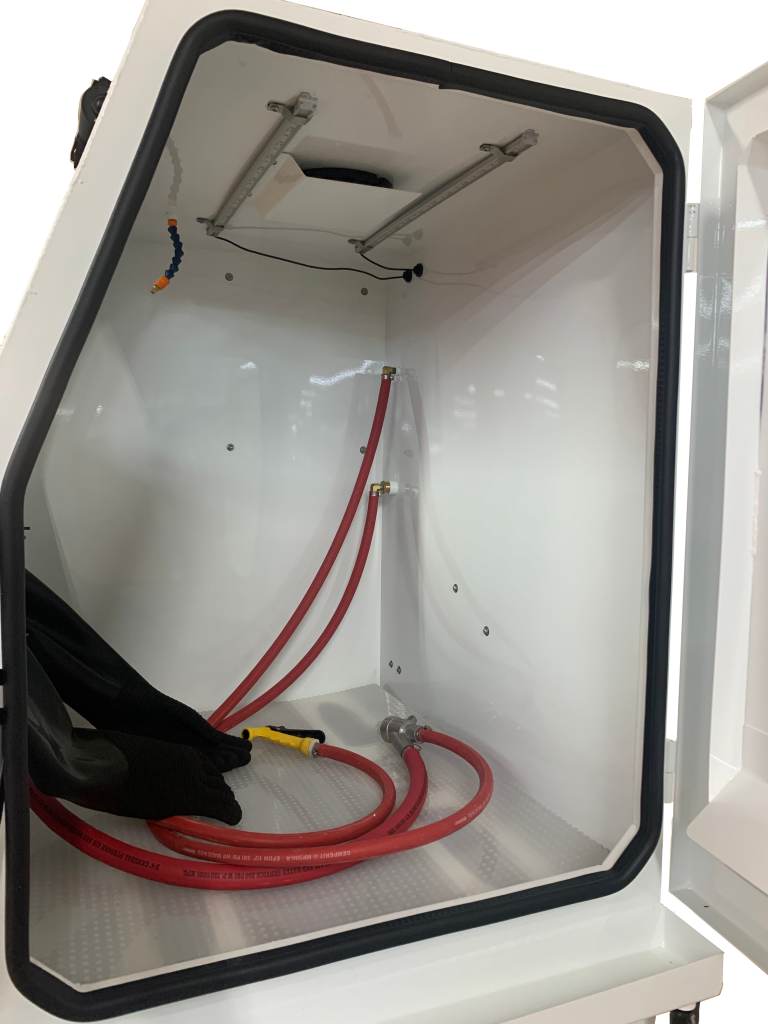

Enter our new Ultrasonic LLC 3200 cleaning cabinet. This piece of equipment is remarkable and can clean things we can’t normally get access to. By utilizing this system we can remove years of old coked oil and debris from engine parts. Aluminum heads look remarkable just after 1 to 2 cycles in the machine.

We still utilize a hot tank to remove heavy soils, oil and road grime/debris but as the EPA wants to continue their choke hold on ways to clean we have to step up to a new way of doing things. While the investment is not for everyone, engine shops like ours need something like this to not only clean better but in a better time managed manner. This is yet another addition to our shop to aid us in building great engine assemblies.