Atomizer has come out with their all new Fury Billet Injector line which replaces all Atomizer 3 designed units. The features and benefits are above anything else offered on the market for a race/motorsport injector.

Upgrade your build with FURY injectors, now rated for 600–6000+ HP. Our latest line features upgraded, 100% rebuildable, high-performance replacements for both Bosch 210 and Siemens Deka 220 injectors. Enjoy better flow, reliability, and compatibility with all fuels, including methanol and ethanol.

Every Atomizer injector is hand-built and flow-matched to the hundredth of a cc per second for razor sharp fueling. Each injector we offer is customizable to low or high impedance and can be made to virtually any PPH needed up to 1,525PPH at no extra charge.

FURY ST: Designed for high-HP single injector performance and race applications, offering outstanding drivability and reliability for your customers’ builds.

Its low 1.6 Ohm impedance suits peak and hold driver systems, while a wide spray pattern enhances combustion and power.

Featuring a 5mm extended tip for better fit and spray targeting, it’s ideal for custom and high-boost setups. It supports fuel pressures from 160–325 lbs/hr at 43.5 psi to 500–850 lbs/hr at 90 psi, adapting to various configurations. The EV1 connector ensures easy installation with most aftermarket and OEM harnesses. Built with a durable billet aluminum body, it fits standard 14mm fuel rails and common intake manifolds. Perfect for drag cars, turbo projects, or street/strip builds, the FURY ST delivers reliable high-performance fueling.

BC 210: A high-impedance, USA-made injector that serves as an improved replacement for the Bosch 210 (2200cc) series. It features modern high-flow technology and compatibility with a wide range of fuels and setups.

Upgrade your fueling system with the Atomizer BC210 Fuel Injector-a superior, rebuildable alternative to the Bosch 210 injector, engineered for the most demanding motorsport and high-horsepower street applications. Hand-built in the USA, the BC210 sets a new standard, delivering rapid response, precise fuel metering, and efficient combustion, making it ideal for turbocharged, supercharged, and naturally aspirated engines. Each injector is dyno-proven, flow-matched, and fully rebuildable, ensuring consistent results and long-term value.

Key Features & Benefits:

High Flow Rate: 210 lb/hr (2200 cc/min) at 43.5 PSI, with proportional increases at higher pressures for versatile tuning.

Fuel Compatibility: Works with gasoline (pump and race), alcohol fuels (methanol, ethanol, E85), and CNG-perfect for drag racing and high-power builds.

Precision Engineering: Proprietary Atomizer Flow Technology ensures micro-droplet fuel delivery for efficient combustion and smooth idle.

Durable Construction: Made from billet stainless steel for maximum strength, serviceability, and longevity.

Plug-and-Play: High-impedance coil design is compatible with most OEM and aftermarket ECUs-no resistor packs needed.

Hand-Built Quality: Each injector is hand-assembled, internally blueprinted, and flow-matched in a closed-loop environment in the USA.

Rebuildable: Designed for long-term use and easy servicing, saving you money over time.

Technical Specs:

- Body diameter: 25 mm

- Length (O-ring to O-ring): ~62.5 mm

- Overall length (top to tip, extended): 86.5 mm (5 mm longer tip for improved spray)

- Standard 14 mm fuel rail and runner bore

- Dual 14 mm O-rings (90 durometer proprietary Viton) for superior chemical and temperature resistance

- Bosch EV1 90° connector for optimal fuel rail clearance

- Stainless steel inlet filter basket (requires 10-micron post-pump filter)

Why Choose Atomizer BC210?

- Specifically designed for high-performance and power-adder applications, while maintaining street-like idle control.

- Consistent, clean spray pattern for improved throttle response and turbo spool.

- Built to outperform and outlast generic 210 lb/hr injectors, with full support for rebuilds and service.

SD 220: The SD 220 is a fully rebuildable, precision-built replacement for the discontinued Siemens Deka 220. It exceeds the original’s performance, supports all major fuels, and is engineered for extreme horsepower turbo and supercharged engines.

The Atomizer SD220 is the modern

evolution of the legendary Siemens Deka 220 fuel injector, purpose-built

to fill the gap left by the discontinued original. Engineered for

racers and high-performance enthusiasts who demand more, the SD220

combines the trusted fitment and performance profile of the Deka 220

with advanced materials, superior flow, and unmatched fuel

compatibility. Say goodbye to throwaway injectors that can’t be rebuilt

and serviced. The new purpose-built SD220 changes the game!

Why Choose the Atomizer SD220?

-

Direct Upgrade for Siemens Deka 220:

Designed as a drop-in replacement, the SD220 shares the same dimensions as the FURY. Unlike the original Siemens Deka 220, this upgraded version is 100% rebuildable, making it the perfect solution for builds that require more longevity, reliability, and flow. -

Extreme Flow for Extreme Builds:

Delivers a massive 220 lb/hr (2433 cc/min) at 43.5 PSI and approximately 260 lb/hr at 58 PSI—ideal for turbocharged, supercharged, and high-horsepower racing applications. -

All-Fuel Compatibility:

Run gasoline, methanol, ethanol, and flex fuels with confidence. The SD220 is engineered to handle the harshest fuels and race blends without modification. -

Racing-Grade Durability:

Machined from proprietary USA MIL SPEC billet stainless steel, the SD220 is built to withstand the rigors of professional motorsport and high-performance street use. -

Precision Atomization:

Features a 40° cone spray pattern and multi-orifice design for optimal fuel delivery, efficient combustion, and precise control—even at low pulse widths. -

Fast, Reliable Response:

Lightning-quick seat crack (0.7 ms), full open (1.25 ms), and close (1.3 ms) times ensure crisp, responsive fueling under all conditions. -

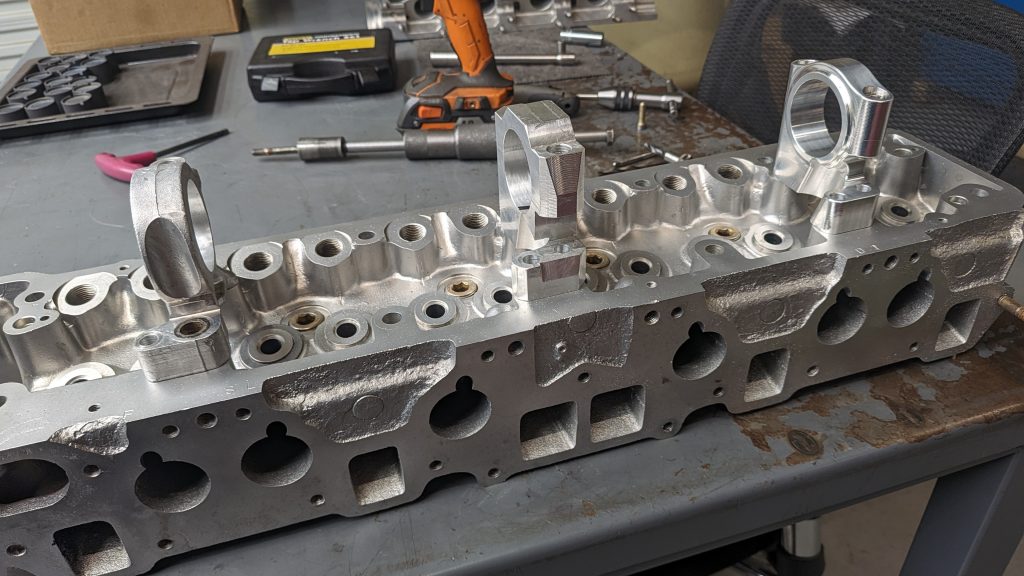

Flexible Fitment:

Refer to dimension photo here for detailed information. -

Built to Last:

Factory-fitted double Viton O-rings provide superior resistance to high temperatures and aggressive fuels. The injector is 100% rebuildable and field serviceable for long-term value.