A few years ago a customer contacted me about having a short block built for his Z32. He was wanting to do a 9:1 compression setup for his street car. He went back and forth about getting something done and finally decided enough was enough. Plagued by issues from previous engine builds he’s had done to keep failing on him with low compression and oil control virtually non existent he sent his last build over to me for a complete overhaul. I received the engine and was a bit terrified at what I saw. With only 2000 miles his current assembly literally stopped dead in its tracks. Rod bearing failure, severe detonation on 3 pistons to the top ring land, inadequate piston to wall clearance…the list kept growing.

So I began to work hard on going through and finding out what needed to be replaced and so forth. A new rod and crank were a must. Thankfully the block was in decent condition to re-hone with proper clearance and move forward. 3 pistons had to be replaced as well due to top ring land deformation due to detonation. The ARP main studs were of the wrong size. The proper units needed were bigger in diameter at the shank to support the added stress levels so those were corrected as well.

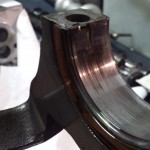

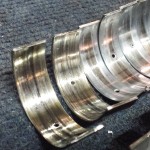

We stepped up to King bearings with a dry film treatment as well as coating his 9:1 pistons with a full coating regiment. During assembly I decided to upgrade the circlips to the all new Krammlox system which is a remarkable and VERY easy system to adopt and I would suggest it to be used in place of the standard circlip.

The crankshaft since it needed to be replaced was modified in house and balanced for the new lighter rotating assembly components. Better oiling systems support more power throughout its life and this engine absolutely will need it.

The short block was honed out to proper specs and fully gone through to my standards. Prepped and ready for its new internals the assembly went together VERY smoothly. The customer pulled the trigger in updating his oiling system by way of doing the crankshaft but he also incorporated my new 8qt racing oil pan. A total of nearly 10qts running through his engine to keep things well lubricated and running extremely cool.

The engine was sent off to the customer and he immediately went to work fitting his heads and other components up. He got the car up and running in a mere 2 weeks. All of this went in his newly acquired slick top. I can’t say im not jealous because he’s done a remarkable job in restoring the car and putting in such a nice assembly.

After a few weeks he reported everything runs exceedingly well and VERY smooth. He states he’s never ran an engine that has performed as well as this one has. Its the details that set the rest apart from what you do and he now sees just how much detail goes into an EPR assembly.

Mod List for Engine Assembly:

JE 9:1 Pistons

Eagle Rods

King Bearings

ARP Main studs

EPR Spec’d/Prepped block

Krammlox

EPR Piston coating

EPR Bearing coating

EPR 8qt Racing Oil Pan

EPR Modified Crankshaft

EPR Ported Oil Pump