Lets face it, with true honesty, with time comes ability and with that ability new responsibilities. So when you begin the quest to increase horsepower your abilities on how fast you can take your car are increased and with that increase in power your responsibilities on component selection and implementation are expected of you. After all, if you plan to make any considerable amount of power with real true performance and response you are 100% in the “peak efficiency” category.

With this new interest in producing power your stress levels of internal components increase. Stock components like piston, rods, fasteners etc are in need of an upgrade and with that upgrade they need to be able to be kept together. That is the “key” phrase…”kept together” So after its all said and done, you’ve spent all your money on high end engine internals yet you’ve done nothing to the block to aid it in the environment you’re about to put it through.

The VG30 is a remarkably strong block. As small as it is, it pegs the scale at 140lbs! SBC blocks are not far off from that weight so in perspective the VG30 packs a HUGE punch for strength for its size that you can absolutely put up to the test with other blocks that are larger in displacement. Short block with a short deck, extra material around the bolt holes, main webs have gussets to aid in reducing considerable amount of flex. The gussets are quite strong for their shape/design. Attaching throughout the casting it is held stationary (main web) securely since the blocks wall structure is VERY thick the webbing doesn’t distort like many seem to think. Out of the many years I’ve been designing parts and building VG30s not a single block has failed at the main web. Adversely I’ve seen several fail due to excessive pressures on the crank which transfers into the main girdle. This shock load bearing down on a single cast girdle reeks havoc on that lower end of things. Cast ductile iron simply can not accept those types of forces for considerable amounts of continuous use. A new system has to be implemented to combat these forces to “keep things together”

With new power breeds new design works and creativity. After seeing others have issues with cracked/fractured main girdles I began noticing on my own with engines that came into my own shop where housing bores for the mains were becoming distorted. I’d go in and dial bore gauge the housing bores to see them out of round by as much as .005″ or more. That’s considerable, and any other machine shop/engine builder will tell you the same. After more and more customers (not all but a fair amount got me wondering a bit) I began to come up with a system that improved the engines ability to maintain its integrity under severe loads better and take the abuse from rotating and combustion stress exerted on the crankshaft.

After a few weeks we had a prototype accomplished in house with a mock up of a main cap and girdle attachment. The goal was to improve the system as a hole to ensure that for those aiming for high power and consistency that system was going to encase what they needed and keep their investment alive and well. To perform at its peak ability and continuously was the main focus.

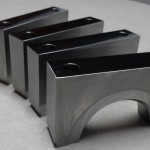

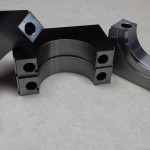

The caps are made of billet steel (90,000 tensile strength) and the girdle plate is cnc cut and formed then plated to give it a uniform finish. All components are built right here in the USA with quality and detail unmatched. The system was designed to retain the existing main stud hardware (ARP) offered currently for the VG30.

Details:

Billet main caps w/ steel girdle plate. This setup obtains current dimensions so you can use the ARP hardware offered currently on the market. This is a complete solution to tackling flex and distortion issues associated with a single piece cast girdle setup.

EPR Billet Steel Main Caps offer excellent strength at a reasonable cost. They’re made from precision-machined high strength steel, which has the proper balance of strength and flexibility to allow transfer of increased shock loads to the crank and bearings. These main bearing caps will improve your engine performance and reliability by eliminating main cap walk and reducing main bearing bore distortion.

Benefits/Characteristics

• CNC machined

• Manufactured from billet steel

• Stabilizes the entire crankshaft rotating assembly

If you are building a VG30 to the 800+whp or more this is the setup that will ensure your engine sustains the abuse time and time again. This system is better suited to locate the crankshaft for any application and all HP figures but consumers aiming for high power production this setup is an absolute must.

Line bore/honing is required for proper fitment. Please consult your preferred machine shop for pricing and details or you can send your block to me for proper machining and setup for this system.