Wasn’t long ago I was called up from my good friend Alex H from N.M Imports about an R35 project. I was curious about it and talked with him in great length about the proposal and plans for this project. After our discussion I decided to take on the project to further advance my ability in other Nissan platforms.

As some of you may recall I had posted a blog entry on my site about this VRs arrival. I listed the new rotating assembly details from GTC website and furnished some images showcasing the companies details on their stroker crankshaft and rod combo. After receiving the goods directly from GTC work had begun. A set of custom 10:1 compression pistons were ordered from CP. HD wrist pins and their custom package THG rings were included. New Kramm locks were utilized to retain the wrist pin inside the pin bore.

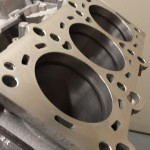

Since the original engine grenade itself into thousands of pieces into the bottom of the oil pan a new numbers 2 GTR block was purchased along with a new lower pan assembly and new oil pump. I had to make a new tq plate to use on this block to hone the plasma cylinders correctly. Simulating the tq and stress of the block to hone properly was VERY key in this assembly. The plasma lining on these engine blocks are very sensitive so it took a considerable amount of time to properly hone the blocks cylinders.

Attention was put into the VRs cylinder heads as well to not only give it better airflow through the intake ports but the exhaust ports as well. A race 3 angle valve job was performed. Heads were then CBN surfaced and then moved onto the head stands to undergo some solid changes. The intake ports were bowl blended to transition the valve job into the intake port and the exhaust ports were fully ported to optimize exhaust flow to the turbine housings for better boost and faster response.

The CP pistons were fully coated (tops and skirts) and the main and rod bearings were coated as well with a dry film lubricant application. Everything was then measured for concentricity, oil clearance configuration etc. Once final cleaned the engine began its final stretch home to being a new heart for this GTRs frame.

The was completed and picked up by Alex from NM IMports personally and transported back to his shop where he then began the grueling process of reinstalling all other components and getting the car up and running. Currently the car is under a break in period to ensure good ring seal is present and all mechanical pieces are worn in properly. Dyno tuning sessions are soon to come once some new ID 2000 injectors are installed. Some preliminary trial testing showed the increase in airflow and power this new assembly makes has already demanded more fuel. More details to come once final figures are presented!

Mod list

GTC 4.1 Billet Crankshaft

GTC Forged Connecting Rods

CP 10:1 Compression pistons

CP HD Wrist Pins

New Numbers 2 OEM Nissan Engine Block

New Oil pump

New OEM Bearings

EPR Piston Coating Service

EPR Bearing Coating Service

Race 3 Angle Valve Job

Ferrea Dual Coil Valve Springs

Ferrea Titanium Retainers

EPR Cylinder Head Modifications