I get a lot of phone calls every week regarding parts selection and pricing on components. Many ask me whats the best piston to run or what I feel is the best for certain applications. While I have my own view on certain parts and criteria in which they can be used for or should be used for I feel that ultimately the customer should be educated well enough to make the best decision for his/her self instead of running what X person suggests. After all, I can only suggest what I consider the best or most viable option, the customer at the end of the day is the one who ultimately makes the decision on the final call of what they want to purchase and run in their assembly.

So lets talk about what pistons on the market are available (off the shelf) for the VG30DE engines. We have CP Pistons, Wiseco, Ross, Probe, (discontinued recently but if you can find a set online new GRAB THEM!) JE, (which I have found out are made in Wisecos factory) & Arias. Im sure there are some others that are available or made for our platform but these are the ones that are most commonly used in building a VG30 engine.

The two pistons I’m going to select to make a good comparison on are between CP and Wiseco. The reason for this is because out of 10 builds I produce at random these are the two most widely used pistons in the VG30 outfit. So I will do a break down on comparisons regarding each piston and what I personally like about each one over the other and the drawbacks.

Lets start with WISECO PISTONS. Great piston, quality, 2618 forging, readily available, affordable and has some great qualities to list. They are among one of the most top picked pistons for the VG30 and are advertised more with rebuild kits than most others, mainly because of the attributes I stated above.

So what are some specs that I like about the Wiseco piston (Part # K549M88). Lets look at the top ring land. It is the largest (tallest) out of any of the top ring lands on any other forged piston on the market. It has integrated detonation grooves that prevent carbon-buildup from locking up the top ring and help keep the air and fuel in suspension. The accumulation of gases that get by the top ring can unseat it, and the pressure groove delays this action. They protect the top ring by disrupting detonation waves as well. These grooves limit the piston/cylinder contact during high temperature and RPM. This is the only piston that I know of that has this feature standard off the shelf in their design.

Another feature is a floating pin bore. What does this mean? A floating pin bore simply means that the pin once installed in the pin bore of the piston it rides on a thin film of oil which is commonly called pin floating, hence floating pin bore. Oil is supplied through a single oil feed hole that is provided by the bottom oil expansion ring groove. It is very important to clearance the pin bore for the wrist pin on moderate to high HP engines or engines that see a lot of abuse. The added clearance helps prevent galling and allows for a smoother rotating assembly and helps keep the parts cooler and working order longer.

Thin ring technology, this is great because the thinner the ring is the less friction it has going up and down in the cylinder bore. The trade off is the “type” of ring you run that comes in the piston kit from Wiseco. Wiseco uses a standard scraper 2nd ring which acts similar to a napier ring but not quite. Its positive function on scraping the excess oil off the cylinder walls helps in preventing oil consumption as well as blow by relief. A napier or THG (tapered hook groove) ring provides a superior scraping affect and prevention of blow by compared to a standard scraper ring. The top ring is a chrome steel nitride ring that resists high heat, less friction wear resistance and is highly durable. The oil or expansion rings are standard ear angle which are common on most pistons.

Wiseco pistons feature a straight side wall which reduces overall weight of the piston, which is nice, but does lend a draw back that creates a thin spot surrounding the outside area of the pin bore. Some consumers have had issues with the Wisecos cracking around the pin bore and I’ve diagnosed this issue to be directly related to them not adding clearance to the pin bores as I’ve mentioned above. You have to remember the more abuse you put on parts the more they will want to move and distort, giving them some breathing room or area to move greatly reduces premature failure. This rule of thumb can be applied to nearly every aspect of a race engines parts.

The Wiseco shelf piston weighs in at 341 grams making it one of the lightest pistons on the market. That’s a good thing because the lighter you can make a rotating assembly the more response it will have and it will enable the engine to rev more freely and effortlessly.

So overall I give this piston a thumbs up for not only being affordable, readily available,but also having the tallest ring land of any piston but its one of the lightest pistons on the market.

Now lets talk about the CP PISTONS. Robust, 2618 forging, radius shoulder side walls, shorter piston by design, premium machining details, and reasonably affordable. The CP in is my favorite piston and for a few good reasons.

The first thing I want to bring up is that this piston as well has a floating pin bore design. However what makes this one different is that it has a twin feed for oiling of the wrist pin. Added oil prevents unwanted heat build up and certainly aids in keeping the pin coated in oil more efficiently. Wrist pins are made of 5100 series chrome moly steel just like the Wisecos are. HP rating of 600HP PER PIN (Both Wiseco & CP)

The CP piston does not have a taller top ring land but the deck thickness from the inside of the piston at the underside of crown to the top of the crown is solid. Even though the Wiseco has a taller top ring land it isn’t solid the entire diameter on the underside of the piston. The design in the forging is different than that of the CP.

CP runs a double walled thick 2nd oil ring which is very stout and does a decent/good job at retaining oil down to the sump. The top ring is a single walled thickness and is chrome nitride steel like the Wiseco variant. The CP does not use thin ring technology but thats ok, I feel they make up for it in the attention to detail with their machining of their pistons. CP does however use an accumulator groove which is a V shaped groove machined in the 2nd ring land to collect excess blow-by between the top and second ring. This groove collects residual gasses during combustion and alleviates top ring flutter while increasing ring seal. I normally get better compression numbers and ring seal with the CP ring package than I do with a Wiseco but every engine is different as well as the application in which they are built for so take that statement with a grain of salt. Its just something I’ve picked up on in dealing with these pistons for many years. The oil expansion ring is standard ear design like the Wiseco so those are on part with each other.

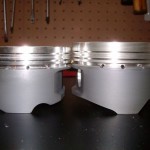

Radial shoulder side wall. BIG improvement over the Wisecos. At the pinch near the pin bore of the piston between the Wisecos and the CP, the CP trumps the Wiseco in thickness by nearly .050″. Thats quite significant. Having the shoulder side wall radius machined does yield the CP as the heavier contender as there is less material that has been removed but in my eyes the rigidity factor and material thickness in this key area is more reason to run this piston over Wiseco. The CP weighs in at 347 grams making it 6 grams heavier than the Wiseco unit.

BUT there is a price factor to take into consideration. Wiseco, while very formidable comes in at approx $620 USD give or take depending vendor of choice compared to CP which retails anywhere from $775-$900 depending the vendor. Thats a significant difference in price between the two. So ultimately the consumer really has to weigh out their options on what they want to invest in. I honestly like both pistons for their own reasons. If you are targeting a price point, Wiseco hands down is the way to go. If you are more concerned about quality of machining and overall improvements over what Wiseco offers CP is hands down your choice. There really is a lot to take into consideration when looking at these two pistons. Its a tough choice but I want consumers to be educated to what they are buying and not fed a bunch of hearsay from random individuals. My personal preference…well I am more of a refinement type of individual so my trust lay with CP but let me say this, I’ve built MANY engines that have made 800-1000HP using the Wisecos with no affects at all. If built properly and details attended to, the Wisecos can have a solid chance to become your next piston choice.

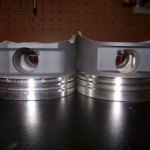

Here are some side by side comparison images of both a CP piston and a Wiseco piston for you to see.

I hope if anything you’ve seen differences as well as advantages between both units shown today. Remember both pistons are good for their own reasons and can withstand a lot of power and abuse. Choose whatever piston you want to run for good reason rather than by what some random individual says. It always pays to do your homework and research the details so you make a better conscious decision on what parts to buy. And ALWAYS consult your engine builder/machinist they normally have the upper hand on what is good and what isn’t from experience and handling products. These are the individuals that really know and can help you decide beyond what research you’ve done on your own.

Thanks for reading!